If you’ve ever looked at the price tag on a high-end camera lens and wondered, “Why does this tiny piece of glass cost more than my first car?”—you’re not alone.

But once you understand the jaw-dropping level of engineering, craftsmanship, and precision that goes into every lens, it actually starts to make sense. Whether you’re a seasoned pro or a hobbyist with a passion for photography, this behind-the-scenes look at how lenses are made will completely change how you see your gear.

Let’s dive into the step-by-step process of how camera lenses are created—and why they’re worth every penny.

1. It All Begins With Optical Glass

At the heart of every lens lies a seemingly simple block of optical glass. But don’t be fooled—this is no ordinary glass. These blocks are engineered to be as pure and consistent as possible, often costing more per pound than silver.

The glass is formed into pressed plates or sliced sheets, which are then cut into smaller chunks. Think of this as the “rough draft” of the lens—full of potential, but far from finished.

2. Shaping the Lens: Curve Generation

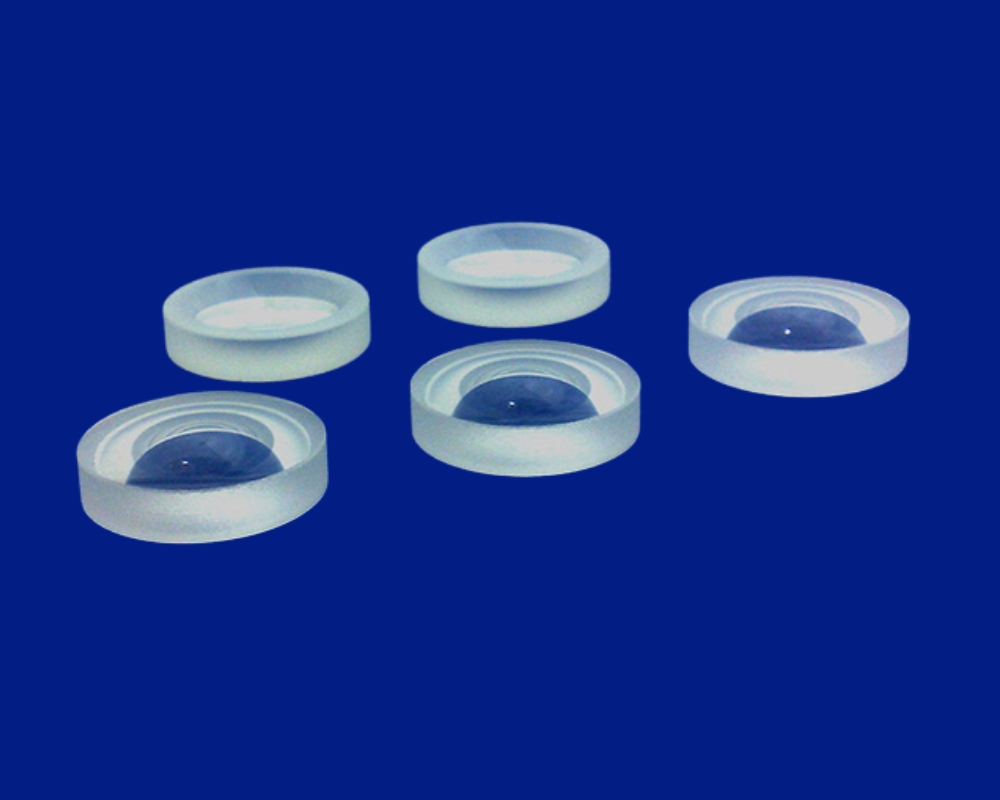

Once the chunks of glass are prepared, they go through a curve generator—a high-precision grinder that forms the initial convex or concave shape of the lens.

We’re talking tolerances that are so fine they can’t be seen with the naked eye—but are absolutely critical to how the lens focuses light. Any flaw at this stage, and the glass is scrapped. Quality control is ruthless, and for good reason: a poorly shaped element will ruin every shot.

3. Grinding and Polishing: A Spa Day for Glass

Next, the lens undergoes a meticulous grinding and polishing process. Using increasingly finer particles and water, the glass is refined until it reaches optical smoothness, measured in nanometers—yes, nanometers. That’s smoother than a single strand of human hair.

This polish is crucial for capturing sharp, vibrant images instead of dull, distorted ones.

4. The Secret Sauce: Lens Coatings

With the lens perfectly shaped and polished, it’s time to apply coatings—the invisible magic that makes modern lenses perform so beautifully.

These aren’t simple sprays. Coatings are applied in vacuum chambers, similar to the technology NASA uses for spacecraft windows. They’re only a few molecules thick but make a huge difference, reducing reflections, improving light transmission, and enhancing image quality.

Each lens surface is meticulously cleaned before coating to ensure perfection. Multiple layers—sometimes a dozen—are applied to surfaces like the front and rear elements of your lens. These coatings protect against scratches, reduce flare, and increase contrast and color accuracy.

5. Building the Barrel: Engineering Meets Durability

Now, the glass needs a home. Enter the lens barrel—a precision-engineered chassis that holds all the elements together while allowing zoom, focus, and durability.

These barrels are made of aluminum, brass, or advanced plastics, and they’re built to survive real-world abuse—from music festivals to mountain hikes. Internally, they also house key components like:

-

The diaphragm (those whisper-thin blades that control light intake)

-

Autofocus motors

-

Weather sealing

Even the inside surfaces are coated to minimize internal reflections.

6. Testing, Testing… and More Testing

Here’s where it gets intense. Before a lens ever hits the shelves, it’s put through a brutal series of tests that would terrify an Olympic athlete.

We’re talking:

-

Drop tests

-

Extreme temperatures

-

Vibration tests

-

Humidity challenges

-

Element alignment inspections

-

Optical testing with tools sensitive enough to detect imperfections smaller than the wavelength of light

The standard? Absolute perfection. If a lens fails any test, even by a tiny margin—it’s scrapped.

7. Autofocus Motors: Tiny Robots with Huge Responsibilities

Modern autofocus systems are nothing short of sci-fi. Today’s high-end lenses include multiple tiny, silent motors that move heavy glass elements with micro-precision—hundreds of times per second.

Types of motors include:

-

Ultrasonic motors (super fast)

-

Stepping motors (super smooth)

-

Linear motors (super precise)

These motors need to be strong yet delicate, powerful yet whisper-quiet. And on top of that? They must last for years—even decades—without failing.

8. Software: The Hidden Powerhouse

All those motors need software to control them. Every lens has custom-coded firmware that’s optimized for different camera bodies and scenarios. The R&D involved in creating this software adds another layer of cost and complexity.

So… Is It Worth It?

Absolutely. When you buy a high-end camera lens, you’re not just buying glass and metal—you’re investing in decades of engineering, testing, and innovation.

But here’s the good news: You don’t need the most expensive lens to take amazing photos.

Modern lenses—yes, even budget ones—are sharper, faster, and more capable than anything available even 20 years ago. A stunning shot taken with a cheaper f/4 lens will always beat a boring one captured with a $3,000 f/2.8.

Final Thoughts

Next time you look at a pricey camera lens, remember everything that went into making it—from nanometer polishing to robot-like motors and space-grade coatings.

But also remember: The best lens is the one that helps you capture your vision.

So go out there, shoot what you love, and don’t get lost in the marketing hype.